How to Choose PVDF Grades for Extrusion

Introduction: Why PVDF for Extrusion

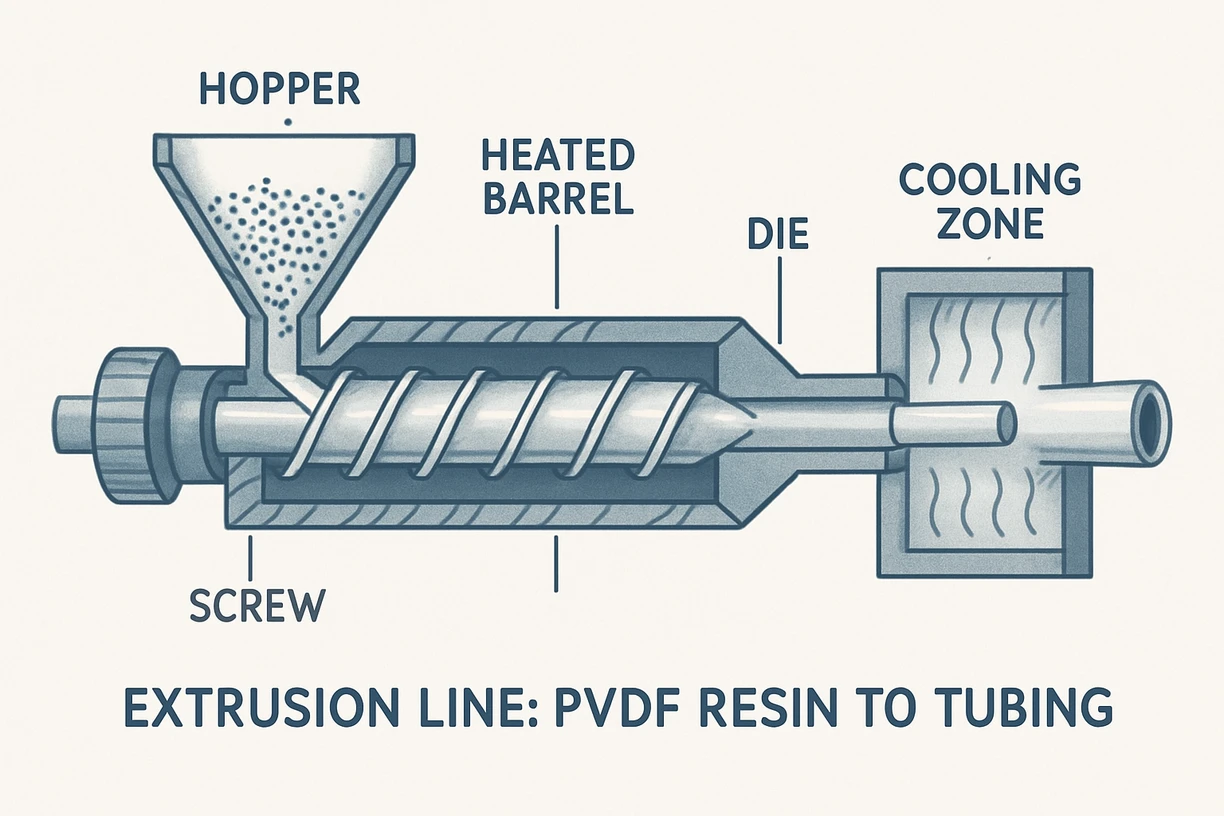

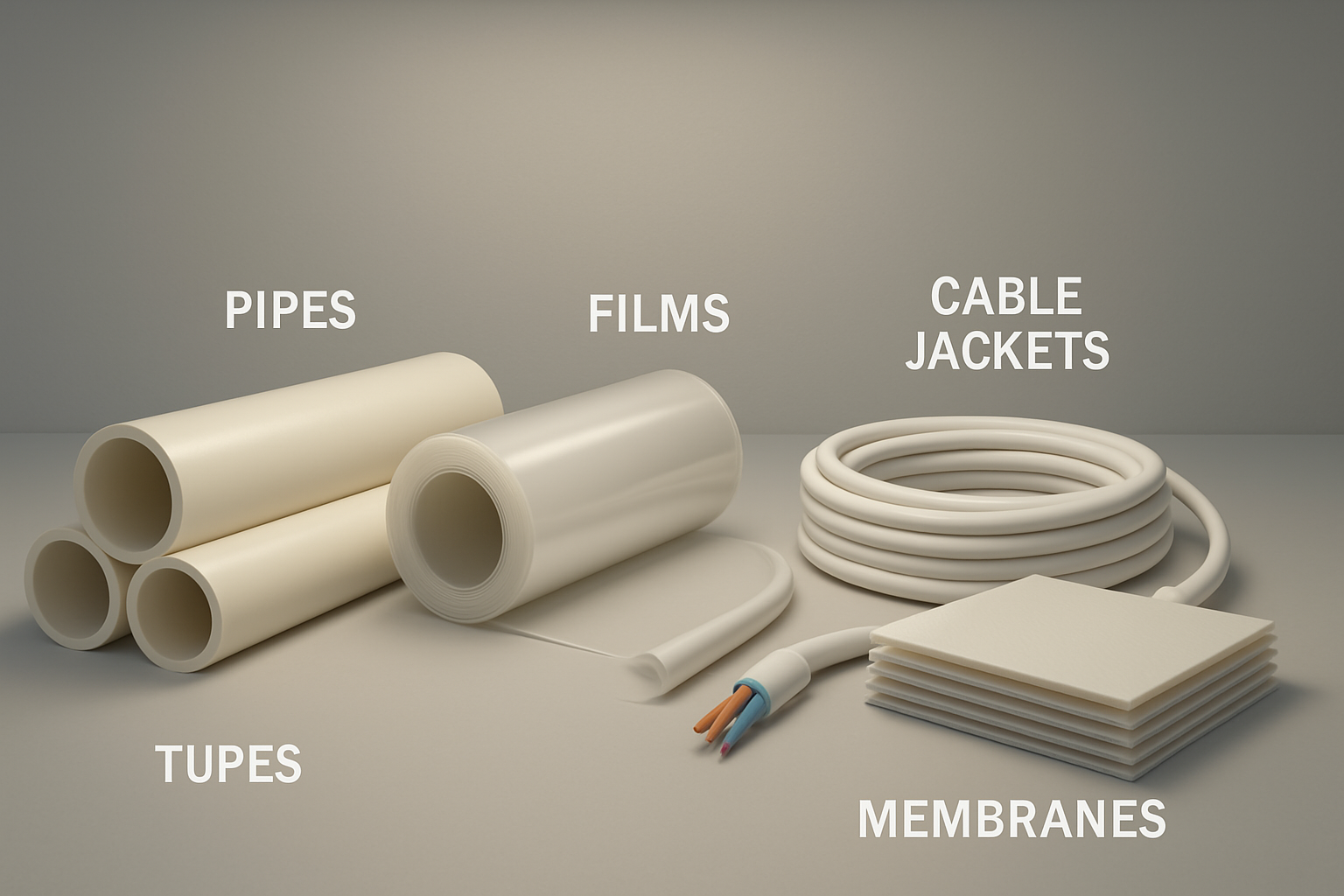

Polyvinylidene fluoride (PVDF) is a high-performance thermoplastic fluoropolymer widely used in extrusion molding due to its chemical resistance, thermal stability, and excellent mechanical strength. Whether you’re manufacturing industrial tubing or high-purity films, PVDF delivers reliable performance.

FOTECH offers tailored PVDF solutions for extrusion lines, helping global manufacturers optimize both product quality and processing efficiency.

Key Factors to Consider When Selecting PVDF Grades

1. Molecular Structure: Homopolymer vs Copolymer

Homopolymer PVDF provides higher rigidity and tensile strength—ideal for pressure-resistant piping or support components.

Copolymer PVDF (e.g., PVDF-HFP) enhances flexibility and transparency, suitable for cable jacketing, membranes, or soft films.

FOTECH’s catalog includes both types, enabling clients to choose based on mechanical and processing requirements.

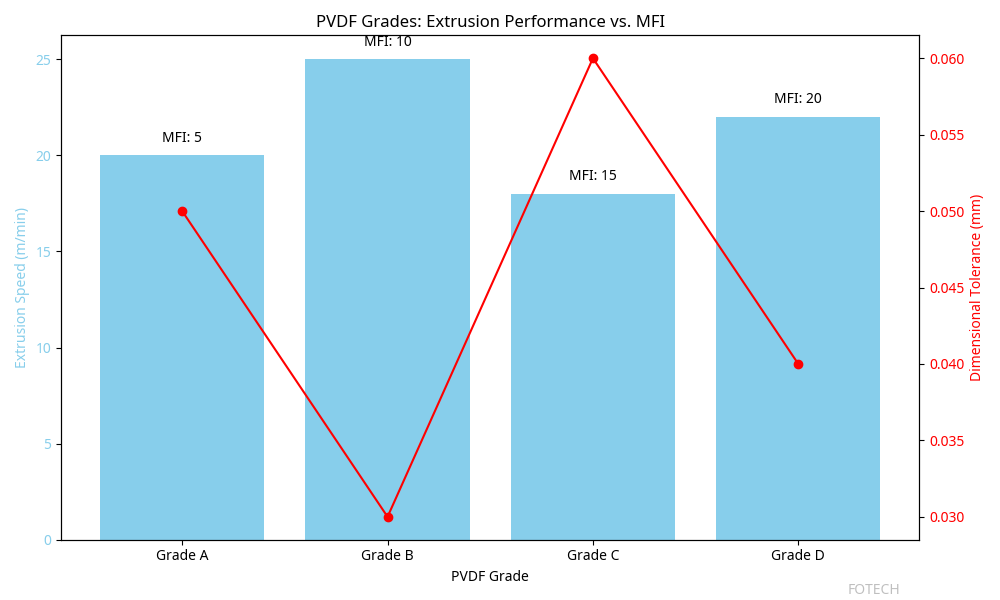

2. Melt Flow Index (MFI)

The MFI (Melt Flow Index) of PVDF indicates how easily the polymer flows at a defined temperature:

- Low MFI (high viscosity) offers structural integrity.

- High MFI (low viscosity) supports high-speed extrusion and intricate profiles.

FOTECH engineers assist clients in selecting the best MFI range for extrusion dies, screw speed, and downstream equipment.

3. Thermal Processing Conditions

PVDF typically extrudes at 200–250 °C, though optimal ranges vary by grade:

- Maintain uniform heating across barrel zones

- Choose corrosion-resistant screws (Inconel/SS)

- Use short residence times to avoid degradation

FOTECH provides full processing guides and recommended setup conditions per grade to ensure extrusion quality and material stability.

4. Target Application Requirements

Choose PVDF grades based on the specific mechanical and chemical demands of your application:

| Application | Suggested Grade Type | Key Properties |

|---|---|---|

| Chemical tubing | Homopolymer, low MFI | Strength, chemical resistance |

| Cable insulation | Copolymer, high MFI | Flexibility, ease of extrusion |

| Water treatment membranes | Copolymer blend | Porosity, hydrolytic stability |

| Battery separators | Copolymer, ultra-fine | Electrical insulation, thin gauge |

Why Choose FOTECH for Extrusion-Grade PVDF?

FOTECH is a professional supplier of advanced fluoropolymer materials, including PVDF resins optimized for extrusion. What sets us apart:

- Full range of extrusion-suitable PVDF grades

- Customized technical support for processing lines

- Global delivery with ISO and compliance certifications

- Proven performance in industries like electronics, chemical handling, and energy

Explore our fluorine polymer product line

Common Pitfalls & Expert Tips

- Avoid overheating: PVDF degrades above 300 °C, potentially releasing harmful gases.

- Purge regularly: Use compatible materials to prevent residue buildup in the screw/barrel.

- Store resins dry: PVDF is mildly hygroscopic—always pre-dry before extrusion.

FOTECH provides technical bulletins and guides to ensure safe and efficient processing.

Contact FOTECH for Expert Material Guidance

Whether you need rigid tubing for corrosive chemicals or flexible films for electronics, FOTECH offers the right PVDF grade and application support. Contact our team for:

- Application-specific grade recommendations

- Technical datasheets

- Free extrusion troubleshooting support

Click here to contact us or request a sample

Conclusion

Choosing the right PVDF grade is essential to achieving high-quality extrusion outcomes. From MFI and processing conditions to application performance, FOTECH empowers your production line with reliable materials and expert support.