PVDF Extrusion Moulding Grade

What Is PVDF Extrusion Moulding Grade?

PVDF Extrusion Moulding Grade refers to a versatile polyvinylidene fluoride resin that combines optimized extrusion flow and injection/ compression moulding characteristics. Fotech’s grade offers:

- Balanced melt viscosity for both extrusion and moulding

- Superior dimensional precision and surface finish

- High mechanical strength and chemical resistance

- Excellent thermal stability and UV durability

It’s ideal for hybrid processes like co-extruded tubing, complex moulded fittings, electrical insulation components, and multifunctional profiles.

Hybrid Applications of Fotech's PVDF Grade

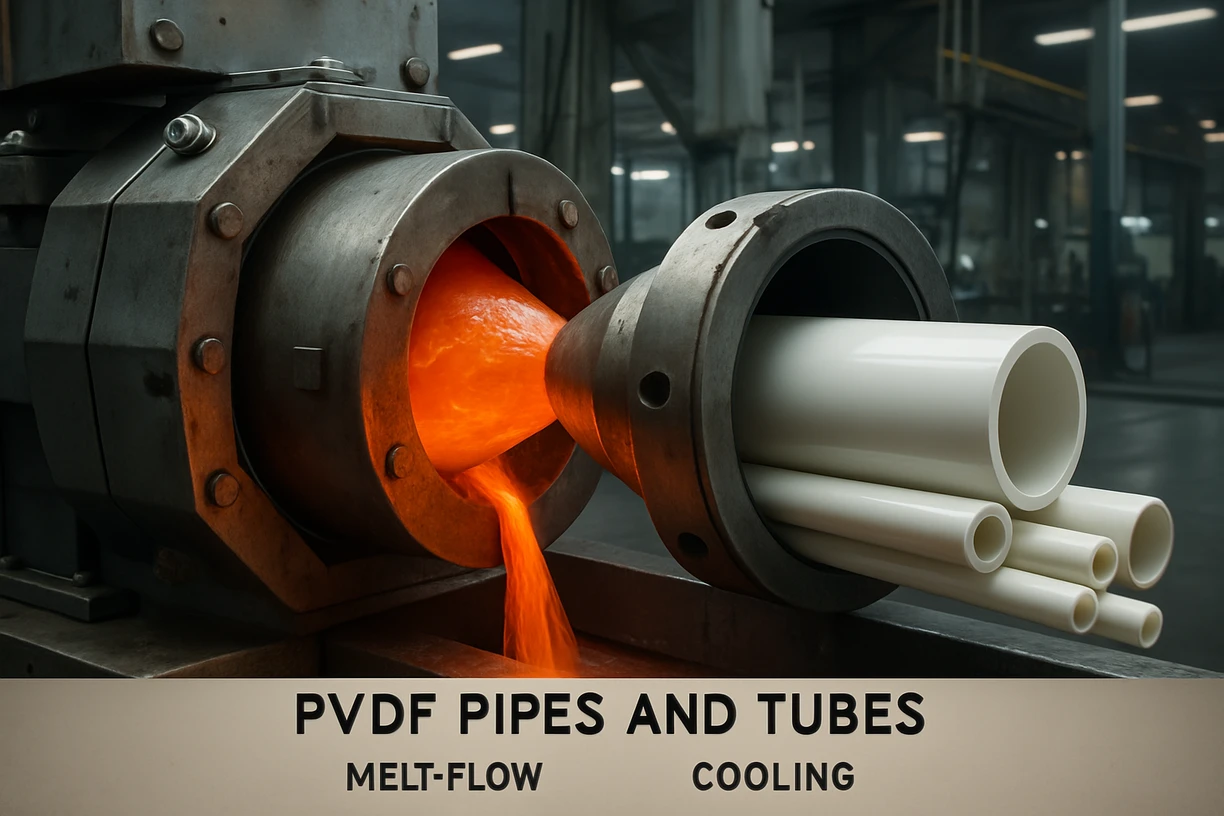

1. Co-Extruded Tubing & Profiles

The balanced flow properties ensure smooth extrusion and subsequent precision moulding of end fittings or flanges.

Benefits include:

- Uniform wall thickness

- Excellent interface bonding

- Mechanical strength maintained

2. Complex Fittings & Valve Parts

After extruding the base profile, moulded grade allows piston-like fittings, plug valves, or multi-port connectors.

Advantages:

- Leak-free precision

- Chemical durability for industrial fluids

- Heat-resistant up to 150 °C

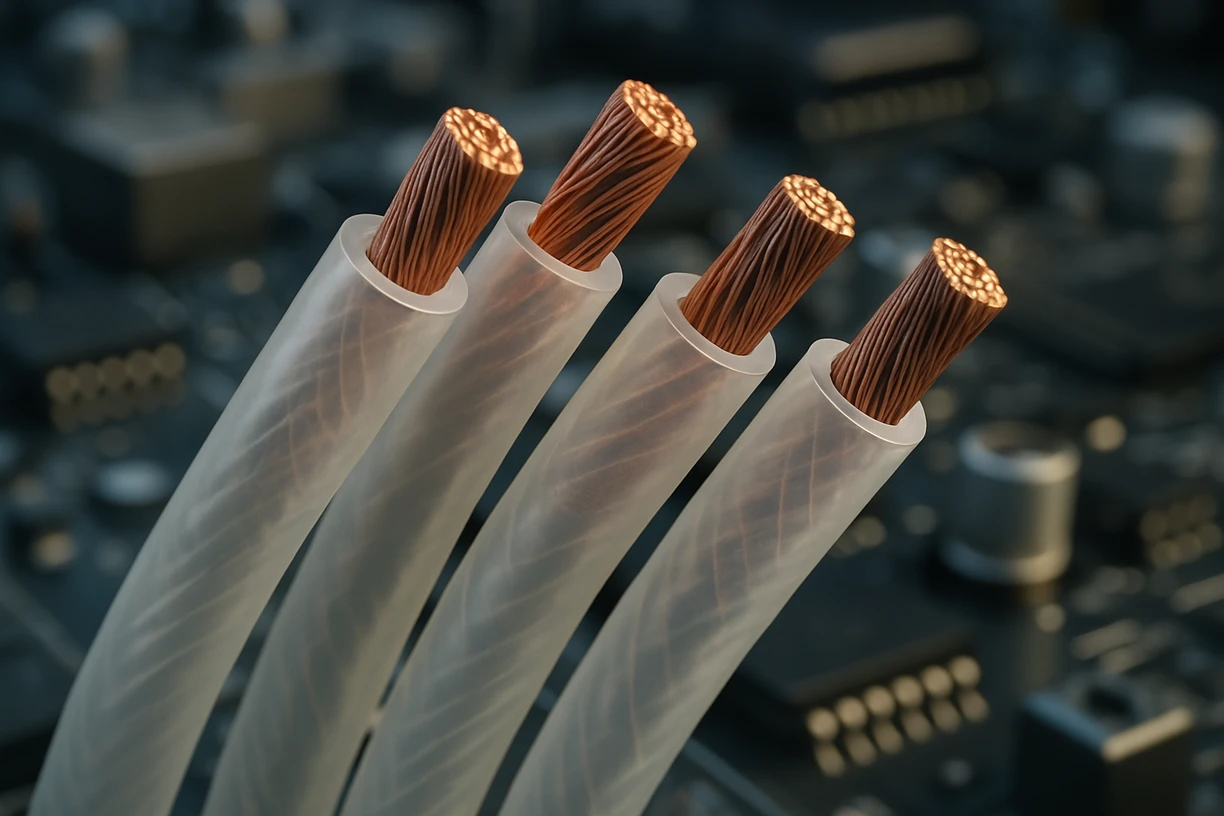

3. Insulated Wire & Cable Profiles

Use extrusion for cable insulation, followed by moulded end fittings—ideal for sensors and aerospace cables.

Highlights:

- FLame retardant, UL‑rated

- Dimensional accuracy for connectors

- Robust under thermal cycles

Why Choose Fotech’s PVDF Extrusion Moulding Grade?

1. Dual-Process Expertise

Fotech develops resin with stable melt and controlled flow that fits both extrusion lines and subsequent moulding steps.

2. Excellent Quality Consistency

ISO-certified control ensures repeatable MFI, color, tensile strength, and adhesion performance.

3. Custom Formulations & Support

Tailored grades for extrusion/moulding chains: pipe fittings, cable connectors, sensor housings—supported globally.

Technical Summary

| Property | Typical Value |

|---|---|

| Melt Flow Rate | 4 – 8 g/10 min |

| Tensile Strength | > 42 MPa |

| Melting Point | ~171 °C |

| Elongation at Break | > 110 % |

| Chemical Resistance | Excellent (acids/solvents) |

For full TDS/MSDS, visit: Fotech PVDF Extrusion Moulding Grade

Conclusion

Whether you need to extrude precision tubing or mould functional end fittings, Fotech’s PVDF extrusion moulding grade delivers optimal processability, precision, and durability. With engineering support and an international logistics network, we’re ready to power your projects.

For enquiries or samples, contact our sales team.

- Loading...

- *Title

- *Content

- Name:

- Eric Chan

- Tel:

+0086-186-68076105

+0086-571-87085102

- Email:

- sales@zjfotech.com

- WhatsApp:

- 8618668076105